Non-contact, high-resolution UT inspection

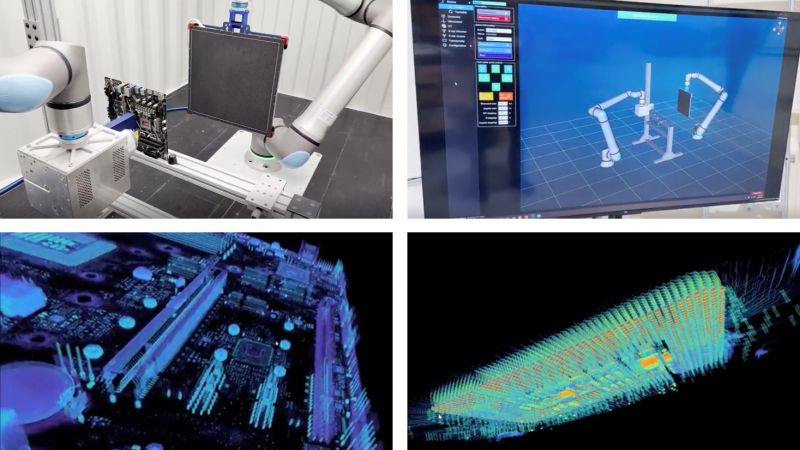

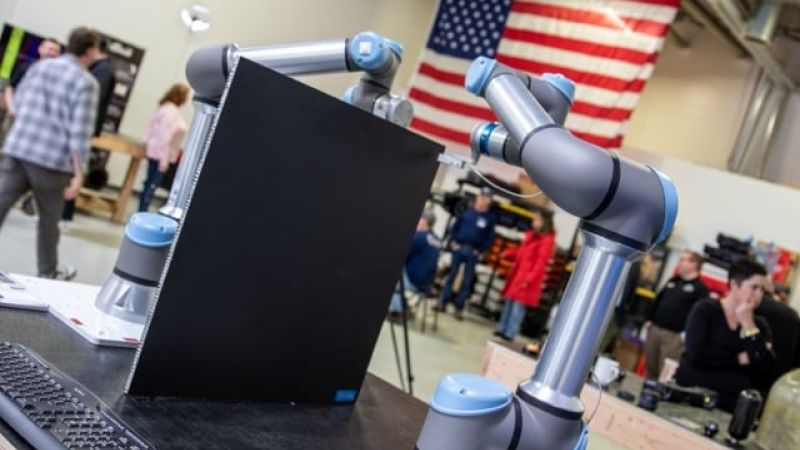

Omni NDE enables using multiple NDT techniques for inspection using our single system of synchronized robots or cobots in conjunction with our Omni Iris software. One of these is XARION Laser-Excited Acoustics, which is a non-contact method that also eliminates the need for a water or gel couplant. It uses a laser to generate an ultrasonic wave within a material and then a proprietary optical microphone to detect the returning waves, enabling the creation of high-resolution images of internal flaws. XARION laser UT is being used with composites and in industries like automotive, aerospace and battery manufacturing for detection of defects such as delamination, cracks and porosity.

Omni NDE has been performing scans with its own XARION system mounted on cobots for 3 years. However, the previous digitizer included with the system had limitations. The new digitizer further opens what an Omni NDE robotic system can achieve using this NDT inspection technique.

What is a digitizer?

A digitizer for UT inspection is a high-speed electronic device that converts the ultrasonic wave data into digital data for analysis to detect flaws, measure thickness and perform other post-processing. High-speed, high-resolution digitizers with high bandwidth memory are essential for capturing accurate details from the UT signals.

Why is the XARION digitizer unique?

Every ultrasound system has a digitizer, including a wide range available from various third-party suppliers, explains James Bennett, CEO of Omni NDE. “But this new one has been designed and built by XARION for robotic inspection. So, it’s not a solution that’s been pieced together from available components.”

This really comes into play with C-scans performed with Omni NDE’s robotic system. “The issue is how do you synchronize the C-scan data collection — obtained as the cobot/robot is rastering back and forth — with the collection of and conversion of the acoustic signal into a digital waveform for each location?”

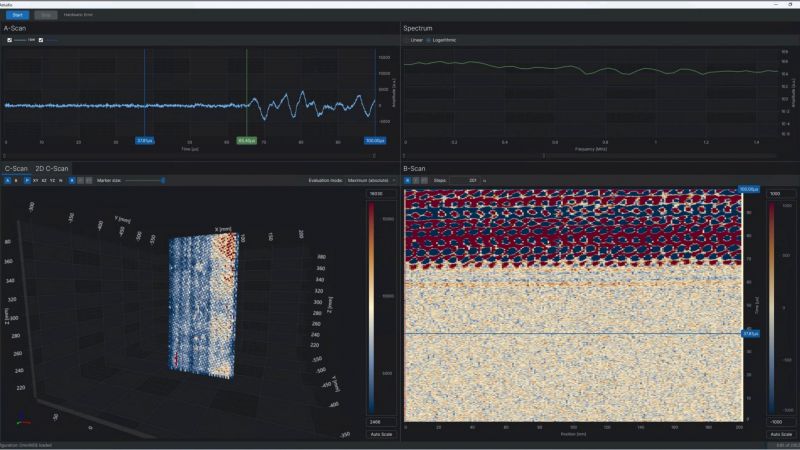

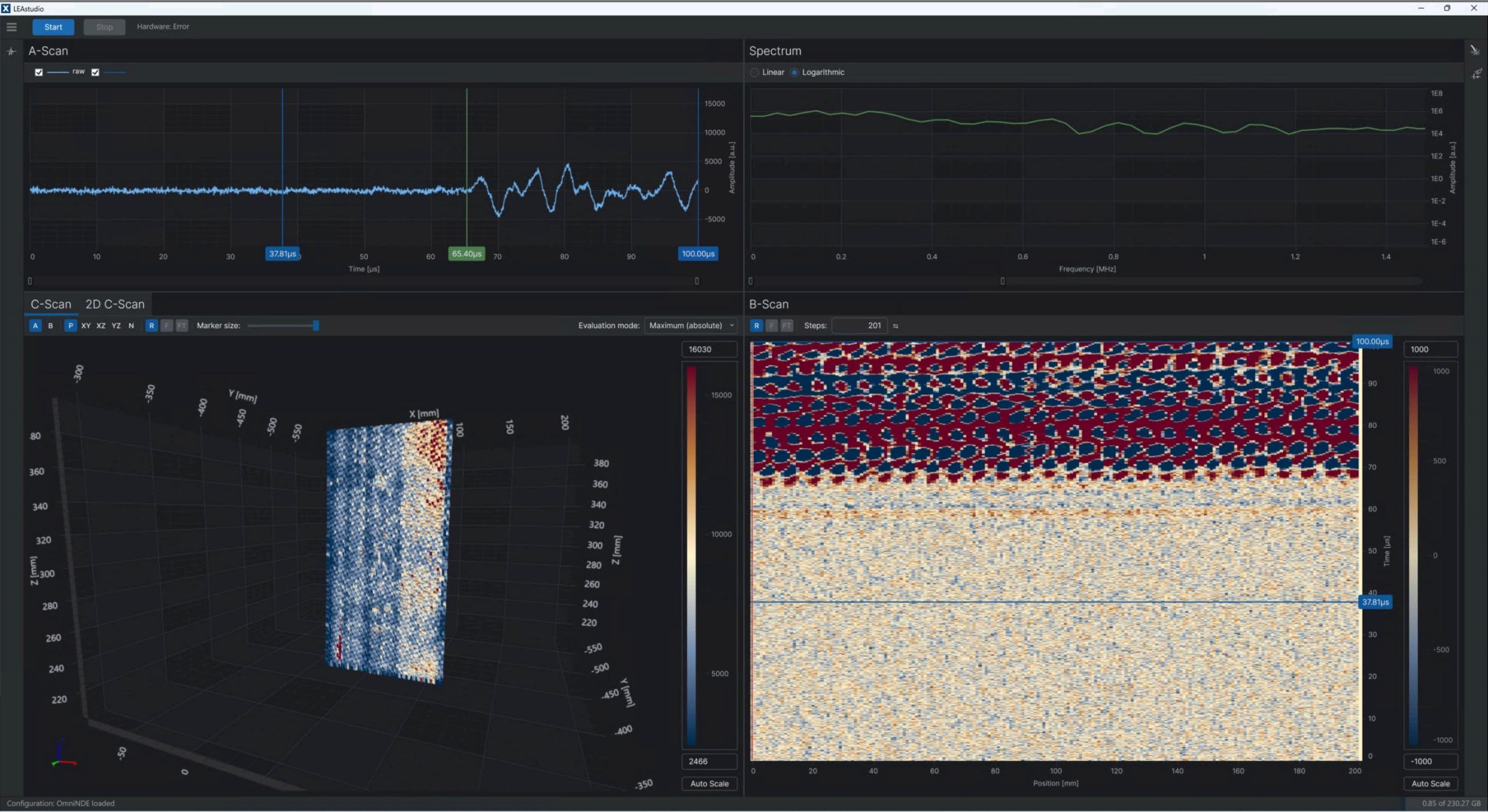

He explains that every time the excitation laser fires, that’s a pixel on a C-scan. “With most typical UT systems, you just get an amplitude/signal strength for every pixel of the C-scan; but those systems are not doing frequency analysis. The XARION system, however, is providing a broadband signal [50 kHz – 4 MHz]. So, the XARION digitizer has to synchronize this, but it’s also collecting way more data for every pixel or every measurement in that C-scan than you would with a traditional UT system.”

“In that system, you would only get one number describing the amplitude of the signal. But with XARION, you’re getting the full waveform, so that’s thousands of data points per pixel. Just collecting that amount of data in real time is not trivial.”

“Going back to synchronizing that data collection with the Omni NDE robots, it requires a combination of hardware and software. This new digitizer upgrade from XARION brings that combination, not only with the hardware to support our real-time robotic scans of curved surfaces but also its LEAstudio software that allows us to coordinate the data collection with the robots and then perform frequency-based analysis on the collected data.”

New analysis capabilities

Upgrades offered by this new digitizer include the ability to do high-pass or low-pass filtering and also wavelet or Fourier transform analysis on the entire C scan, not just for a single signal or single data point, says Bennett. “With the old digitizer, you could do Fourier transform but not wavelet analysis. And while you could perform band-pass filtering for a data set, it often took minutes of waiting, whereas now it’s much more responsive, completed in just seconds.”

“Also, the hardware is now more industrial grade, which means that we can scan very large objects,” he continues. “The old system had a limitation, where it just couldn’t handle all the data for anything beyond 2 x 2-feet. It also struggled with complex curved surfaces. The new system, however, has been designed and built for large data sets collected with robot/cobot end effectors across complex surfaces and contours.”

Bennett notes the new XARION digitizer system also unifies all the hardware — including control and timing of the excitation laser and optical microphone — into a single, unified interface. “We’ve now got this interface working with our Omni Iris software, so we can program inspection paths for all types of curved surfaces and generate scan trajectories. This means we can do arbitrary path inspection using any type of robot or cobot and then overlay the data onto a surface map of the part.”

How does this work? “We can do a surface scan of the part, generate a path based on that surface and then perform the laser ultrasound scan. We collect, process and export the data, then overlay the C scan with geometric accuracy onto the surface of the part in our Omni Iris software. So, that’s a pretty unique capability.”

Have questions? Like to see a demo? Contact us. We’d love to show you what we can do.