Disruptive robotic inspection of composites, electronics and difficult assemblies is upgraded, showcasing abilities to inspect bondlines, core splices, CMC, thick CFRP and more at Ogden, Utah AIMM Center.

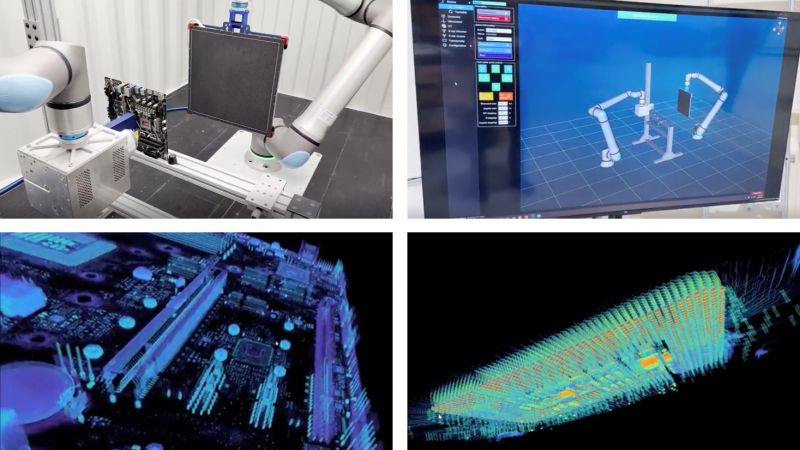

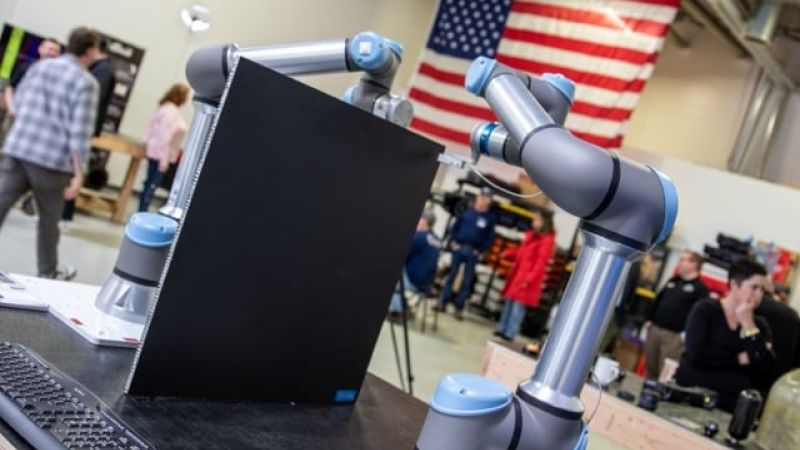

Omni NDE (Tucson, Ariz.) is disrupting non-destructive inspection and evaluation by combining robots and cobots with novel sensors and software for fast, contactless and automated scanning of difficult parts and assemblies. During the April launch of the Advanced Inspection, Methods and Materials (AIMM) Center, Omni NDE demonstrated its Robot CT system and ability to identify defects, voids, porosity and FOD (foreign objects) in parts and assemblies made from metals and fiber-reinforced composites, including carbon fiber (CFRP) and ceramic matrix composites (CMC).

The AIMM center develops and demonstrates next-generation NDT, NDI and NDE technologies. Developed through a partnership with composite inspection and consulting firm CICNDT (Ogden, Utah), it features automated and robotic systems open for demonstration and scan-as-a-service projects, with a team of engineers and Level 3 inspectors that have decades of experience in aerospace, defense, biomedical, wind industry and marine applications. It also houses the full suite of Omni NDE’s novel inspection technologies, including laser ultrasound, laser shearography, thermography, laser surface profiling and X-ray computed tomography (CT).

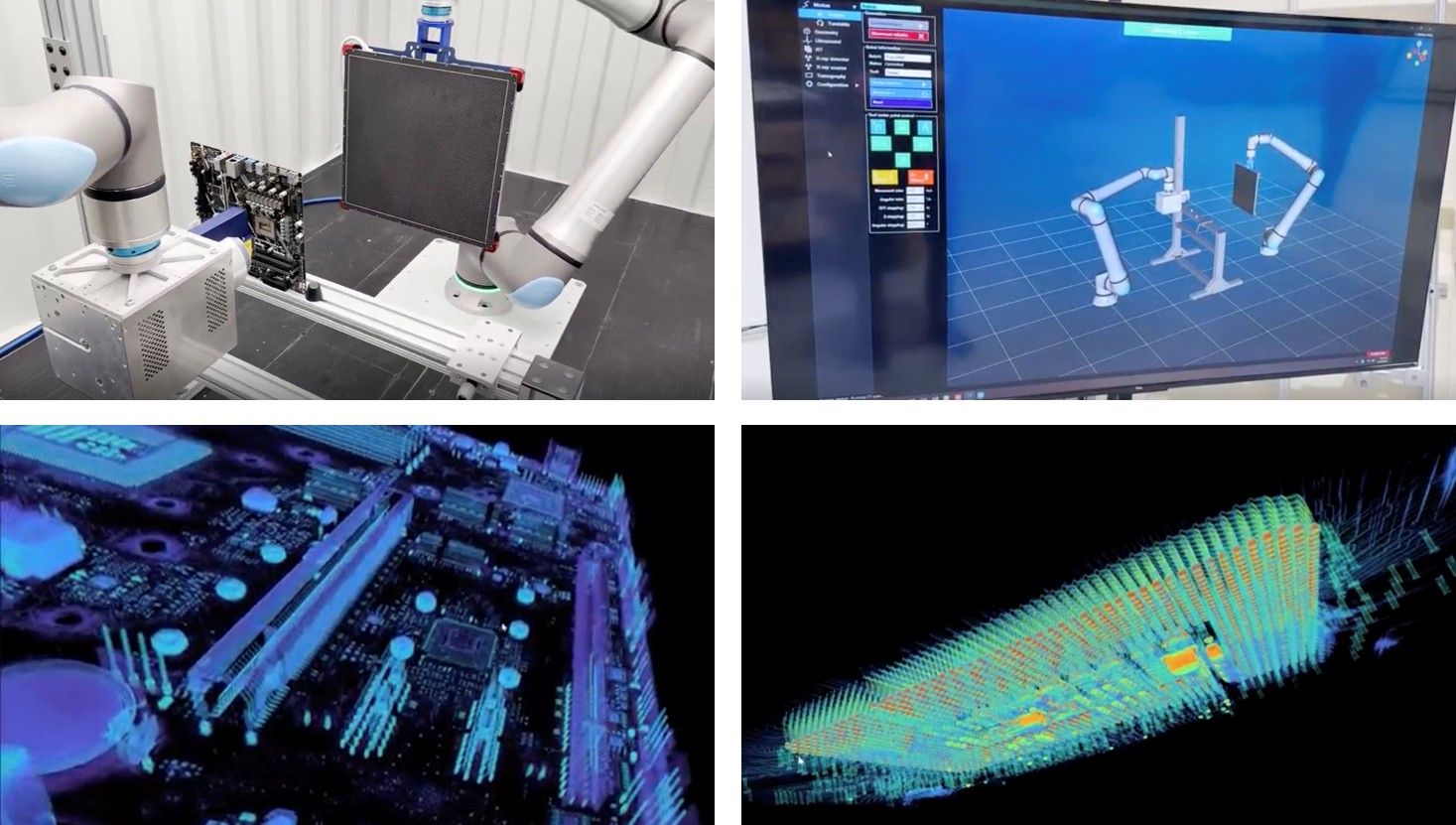

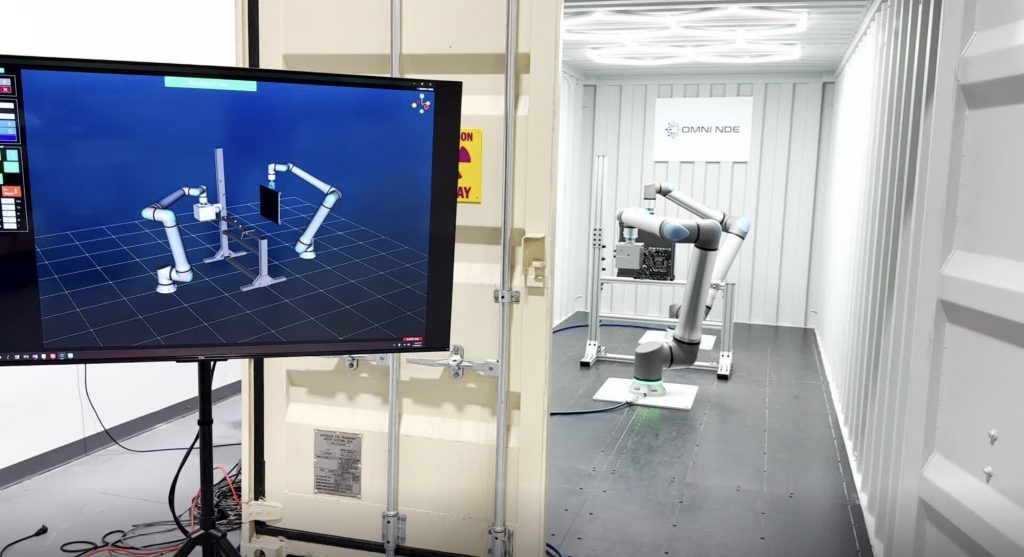

The Omni NDE Robot CT system at AIMM has now been upgraded, replacing the previous UR5 with UR20 cobots for increased payload capacity up to 25 kg, enabling a more powerful X-ray source and larger, more powerful detector.

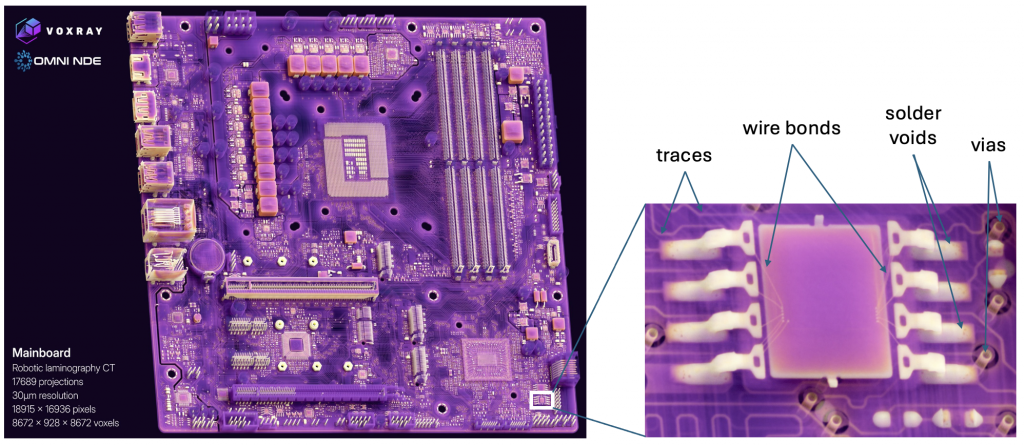

“The new system’s 130 kV X-ray source and 43 x 43-cm detector allows us to scan larger parts but also in detail, down to a 2-micron resolution,” explains James Bennett, CEO of Omni NDE. “For example, we can now scan a 3-meter-long carbon fiber composite part we just received, where that would have been a stretch previously. We have also added a new 4k 360° video system to closely monitor the robot scanning in situ.”

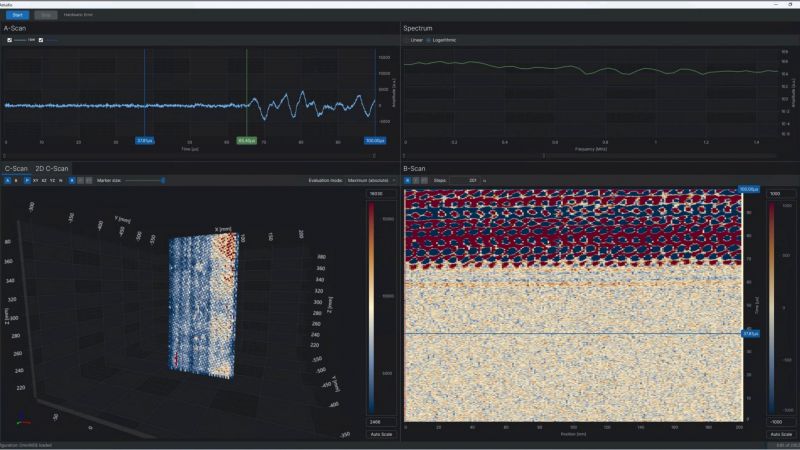

The system also features the latest Omni NDE Iris scanning software. Dual monitors enable control via Omni Iris on one, notes Bennett, while watching the robot scanning process and X-ray detector via the camera system on the other. “You can see exactly where the robots are and their progress in scanning the part, as well as make changes and scan adaptations on the fly.”

“We have completed scans of many different kinds of parts for companies across the U.S.,” he adds. “These parts have included a wide range of metals, CMC and CFRP with various types of cores, including honeycomb, where we are able to inspect core splices and adhesive bondlines in detail.”

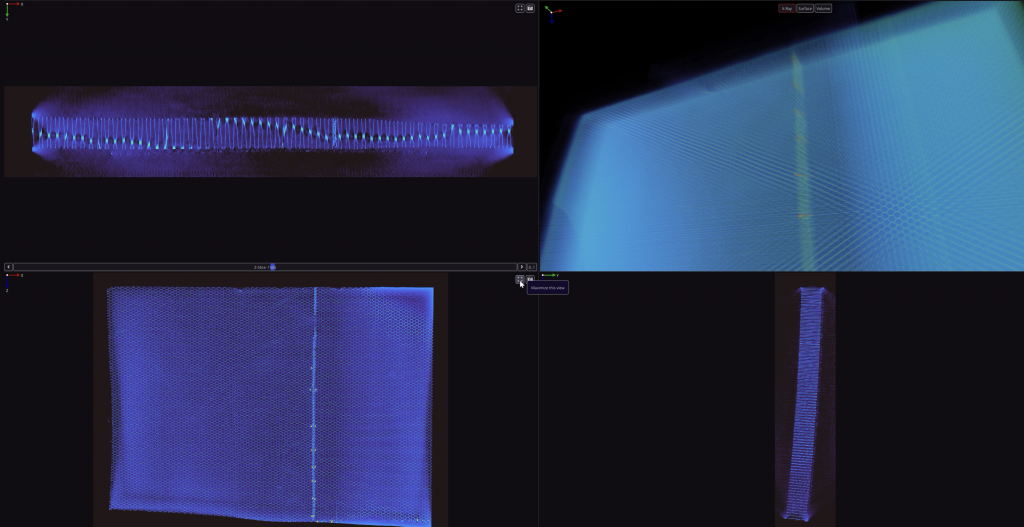

Notably, Omni NDE’s Robot CT moves beyond traditional orthogonal features to diagonal splices and bondlines. “This is difficult to do using other methods such as UT, or even with traditional X-ray and CT systems,” says Bennett. “UT cannot follow diagonal splices and bondlines, nor can shearography or thermography.”

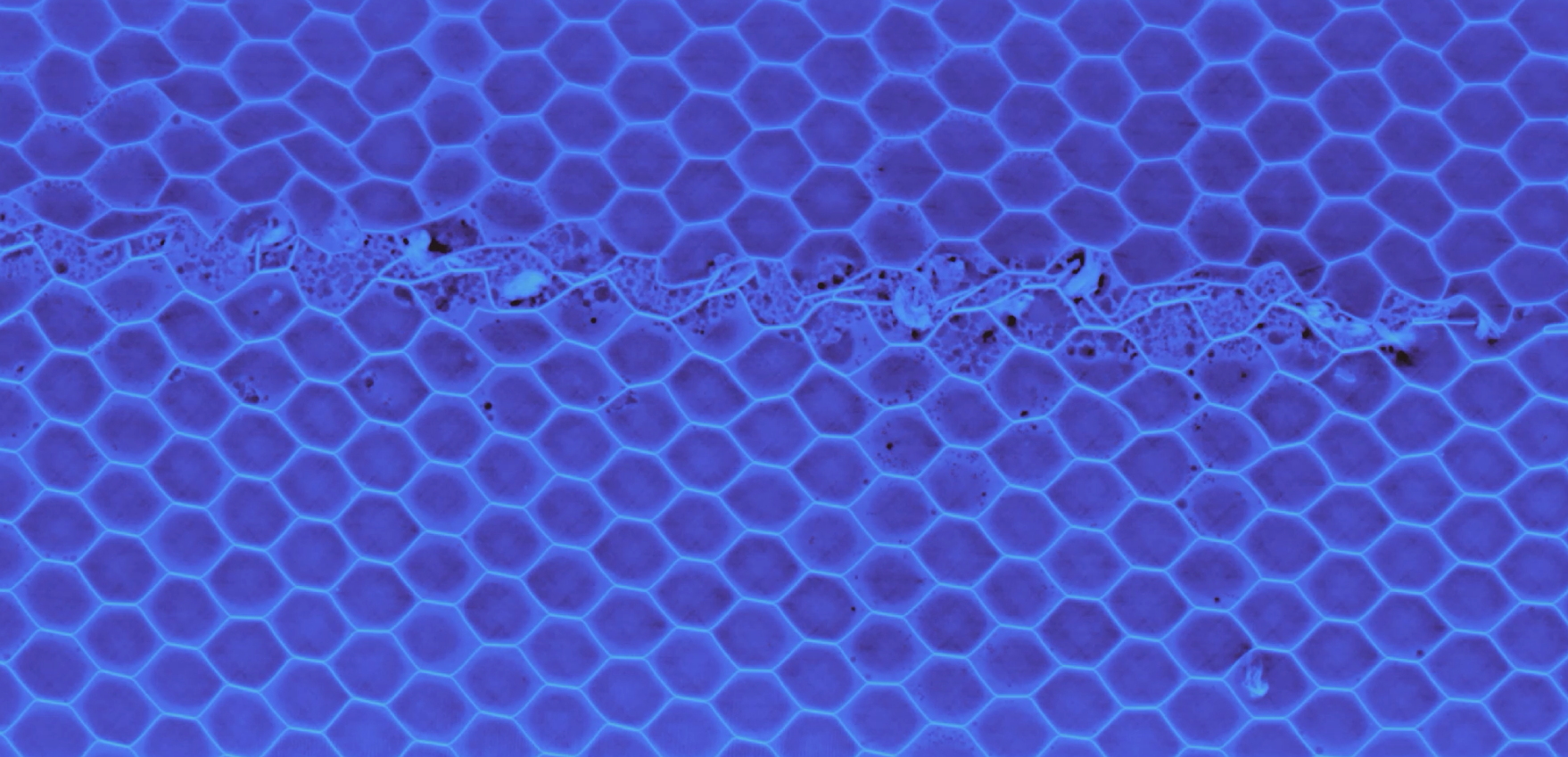

We have also scanned parts with up to seven layers of core with septums. With our system, it is possible to see every layer and the bondlines with the septum between each set of layers, but also the adhesive fillet down the honeycomb cell walls. We have been able to identify not only deliberate defects but also quality issues such as voids, porosity and FOD. But with our Robot CT, you now also have a 3D volume, so that with the appropriate software, you can actually set the visual slicing to that diagonal bond line, and step through the thickness of that bond.”

He explains: “When looking at a 3D volume, you can create a rendering to show the surface of the part, but if you want to see inside then you must slice the object you are scanning along XYZ coordinates. This works fine for most applications, but in the case of diagonal features, you can set the slice in the same plane as that diagonal bondline and then step through each layer like you would in a CT scan.”

However, conventional CT systems require scanning the whole part. “We can inspect only what is needed,” says Bennett. “We can perform laminography on a small region within a large part or we can focus only on the features of interest, whether that be bondlines, core splices, voids, areas of porosity or FOD. And we can not only see the smallest of air gaps but also kissing bond areas where there is contact but only barely. You can actually see tendrils of adhesive that may have been touching during application but pulled apart during the curing process. Our system offers a quick, efficient way to definitively show the presence or lack of disbonds, and there really aren’t other ways of doing that efficiently with other inspection methods.”

Have questions? Contact us. We’d love to show you what we can do.