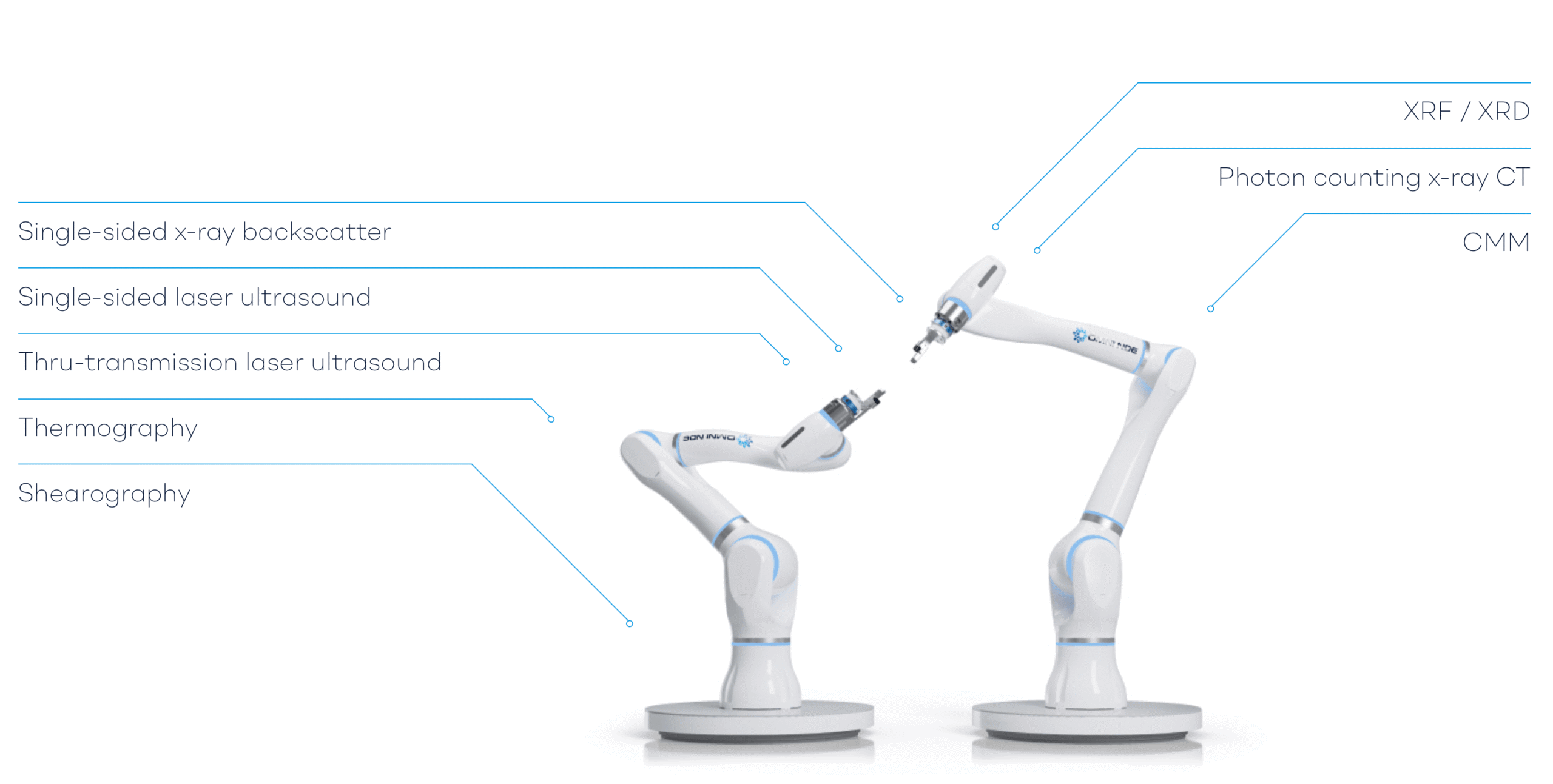

OMNI NDE Technology

Advanced manufacturing demands automated, advanced NDE solutions.

Next-generation NDE enables new capabilities: in-situ inspection of large structures, fast contactless high-resolution scanning, defect measurement, vision into high-attenuating materials and NDE digital twins.

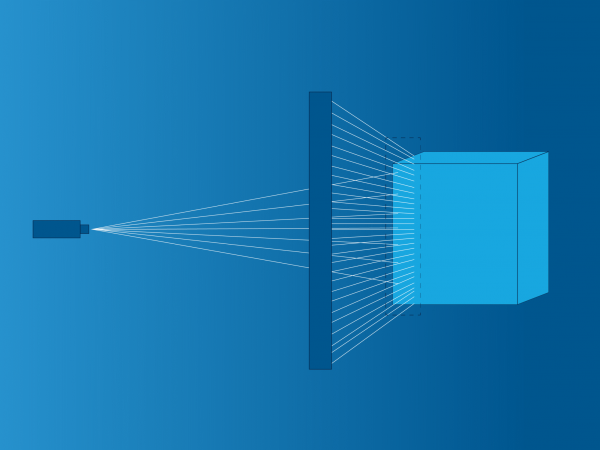

High resolution Robot CT @ 5 micron (0.0002″)

- Scan large objects not possible with conventional microCT systems

- High-energy microfocus x-ray sources (40-150 kVp) allow inspection of very dense materials such as stainless steel and Inconel

Iterative, arbitrary path reconstruction

- Unlimited possible scan geometries

Contactless

- No gel

- No problem with curved parts, even tight curves

- No damage/change to surface of part

- Can measure porosity using resonance frequency of pores (only possible with Xarion due to their broadband microphone)

Broadband

- No need for frequency-specific transducers, instead post-process using digital filters (e.g. bandpass)

- Easily analyze frequency-specific defects

Through-Transmission Ultrasound

- 10x spatial resolution vs. traditional contactless airgap UT

- Fast scanning, up to 450 sq ft/hr

Single Sided Inspection Head (SSIH or Pitch-Catch)

- Can detect defects from only one side of the object when interior access is a problem

Can be operated as a Class 1 laser with a 0.8m barrier

Small, portable system

- Excitation laser from legacy laser UT systems was the size of a car and required significant laser protection

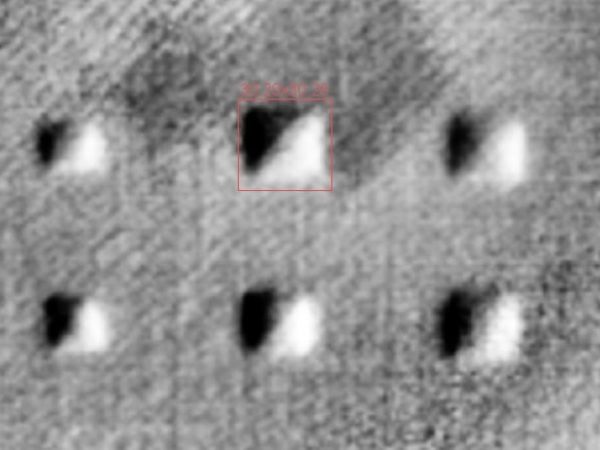

Backscatter X-ray offers single-sided quasi X-ray CT imaging, a capability that has no competing commercial system available. It can effectively detect air gaps less than 80 µm, including cases like delamination.

Surface profilometry provides a high-accuracy surface map, with precision within 25 μm. It is employed to guide the scan trajectory of other modalities.

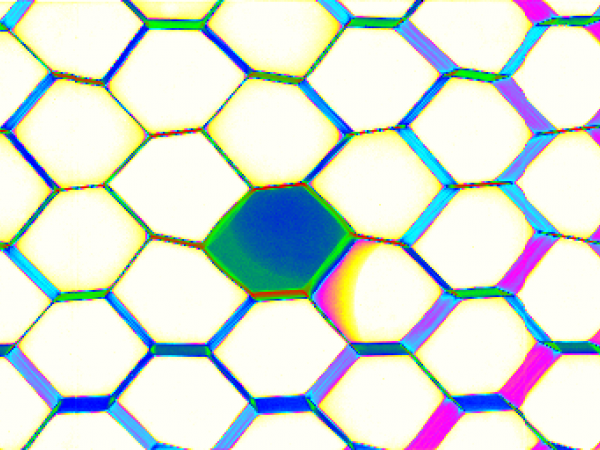

The system is capable of imaging the strain field to identify local weaknesses and defects, such as delaminations and kissing bonds.

The portable system features dual-arm geometric synchronization, offering the highest level of accuracy, and it does not require the use of fences or cages.